E-Waste Gold Refining and Extraction Systems

Electronic waste — from outdated computers and smartphones to broken servers and industrial circuit boards — contains an astonishing array of valuable metals. While base metals like copper make up much of the material, precious metals such as gold and silver, though present in much smaller quantities, are worth significant value due to their high market price and industrial demand.

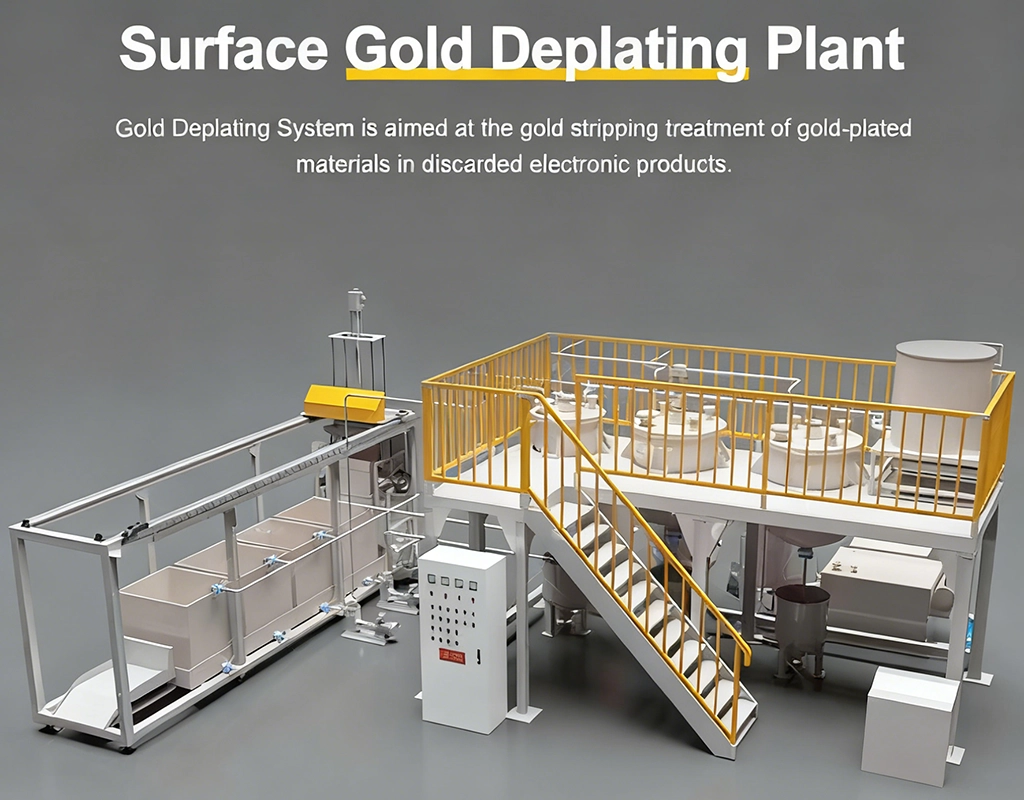

To efficiently and responsibly harness this value, modern recycling operations rely on advanced E-Waste Gold Refining and Extraction Systems — comprehensive technological solutions that go far beyond simple manual processing.

What Is an E-Waste Gold Refining and Extraction System?

An E-Waste Gold Refining and Extraction System is not a single machine, but a complete industrial processing line designed to:

- Crush and sort e-waste material

- Separate metals from non-metals

- Extract gold and other precious metals

- Refine recovered metals to high purity

This holistic approach follows the logical principle of “separate first, extract next, refine last,” ensuring improved efficiency, environmental compliance, and economic returns.

E-Waste Gold Refining and Extraction Systems

How the System Works: Step-by-Step Process

1. Primary Crushing and Sorting

- The first critical phase focuses on breaking down whole electronic components — especially printed circuit boards (PCBs) — through specialized crushing equipment. This mechanical step ensures the physical liberation of metals from plastics, resin, and other non-metal materials.

- Once crushed, sorting technologies are used to divide heavier metals like copper from lighter non-metal fractions. This optimizes the feed for further processing and sets the foundation for efficient precious metal recovery.

2. Precious Metal Extraction System

- After sorting, the precious metal-rich fractions enter the Gold Extraction System. This subsystem is engineered to precisely target gold and other precious metals embedded in the material, using controlled and stable extraction processes that reduce manual intervention and enhance safety.

- Depending on the approach — whether using chemical leaching or specialized stripping methods — the system can dissolve gold layers and collect them in solution without dissolving unwanted metals. Some advanced systems achieve recovery rates close to 99% gold separation before refining.

3. Refining and Purification

- Once gold and other precious metals are extracted into solution, the refining stage begins. This captures metals in higher-purity form, often using precipitation, filtration, or electrolytic techniques to achieve high-purity final products suitable for resale or reuse in manufacturing.

Key Features That Make These Systems Effective

Modern E-Waste Gold Extraction Systems integrate multiple advantages that traditional e-waste processing methods lack:

- 💡 High Recovery Efficiency: Advanced chemical and mechanical systems allow extraction of gold and silver with very high removal rates.

- 💡 Environmentally Responsible: Closed-loop designs with exhaust gas treatment and wastewater control help protect workers and ecosystems from harmful emissions.

- 💡 Flexible Feedstock Handling: Systems can be configured for different kinds of e-waste — from consumer PCBs to more complex industrial boards.

- 💡 Scalable Solutions: Both smaller modular units and high-capacity production lines can be deployed according to volume and budget.

Why This Technology Matters

The amount of global electronic waste continues to grow rapidly as technology cycles accelerate. Many countries struggle with effective recycling and valuable materials remain locked in landfill or in informal, unsafe operations.

According to industry observations, e-waste typically contains higher concentrations of gold than naturally mined ore, making it a lucrative and sustainable “urban mine.”

By adopting professional gold refining systems, businesses can:

✅ Increase material utilization

✅ Lower dependency on raw mining

✅ Generate new revenue streams

✅ Support circular economy practices

Who Benefits Most from These Systems?

These advanced systems are well suited for:

- Large recycling enterprises that need standardized, regulated operations

- New market entrants establishing professional e-waste processing lines

- Factories with high volumes of electronics scrap seeking maximum recovery value

- Regions with strict environmental laws that require compliant processing

The integration of base metal and precious metal workflows also enables users to understand the input-output value ratio more accurately, optimizing profitability and resource usage.

Common Questions About E-Waste Gold Refining

Can gold be efficiently extracted from e-waste?

Yes. When using professional systems, gold recovery from e-waste approaches levels suitable for industrial return on investment.

Is this process safe and compliant?

With closed systems, controlled environmental treatments, and minimal manual exposure to chemicals, modern solutions emphasize safety and regulatory compliance.

What kinds of e-waste can be processed?

Circuit boards, server boards, communication boards, CPUs and other gold-plated components are all valid feedstock.

As electronic waste continues to pile up worldwide, E-Waste Gold Refining and Extraction Systems present a strategic, technological, and sustainable path to unlock the hidden value buried in discarded electronics. They turn complex waste streams into usable metals while minimizing environmental impact.

Whether you’re an established recycler looking to upgrade technology or a new entrant exploring opportunities in the circular economy, investing in a comprehensive refining and extraction system can be both profitable and responsible.