Vietnam circuit board recycling line site

Details

The Vietnam Circuit Board Recycling Line is a turnkey e-waste processing project designed to handle mixed waste PCBs from computers, mobile phones, consumer electronics, televisions, home appliances, and industrial control boards. This case showcases our ability to deliver a high-efficiency, environmentally compliant recycling solution that maximizes metal recovery while ensuring stable operation under Southeast Asia’s humid climate conditions.

1. Project Background

The Vietnamese client, a growing e-waste recycling company, required a complete PCB recycling solution capable of processing 300–500 kg/h of mixed printed circuit boards. Their goals were:

- Achieve high separation purity of copper, and resin powder

- Meet Vietnamese environmental emission standards

- Reduce manual labor and improve safety

- Build a stable, easy-to-maintain plant suitable for long-term expansion

After technical evaluation, we provided a fully automated Circuit Board Recycling Line equipped with dust control, negative-pressure feeding, and an optimized crushing–separation system.

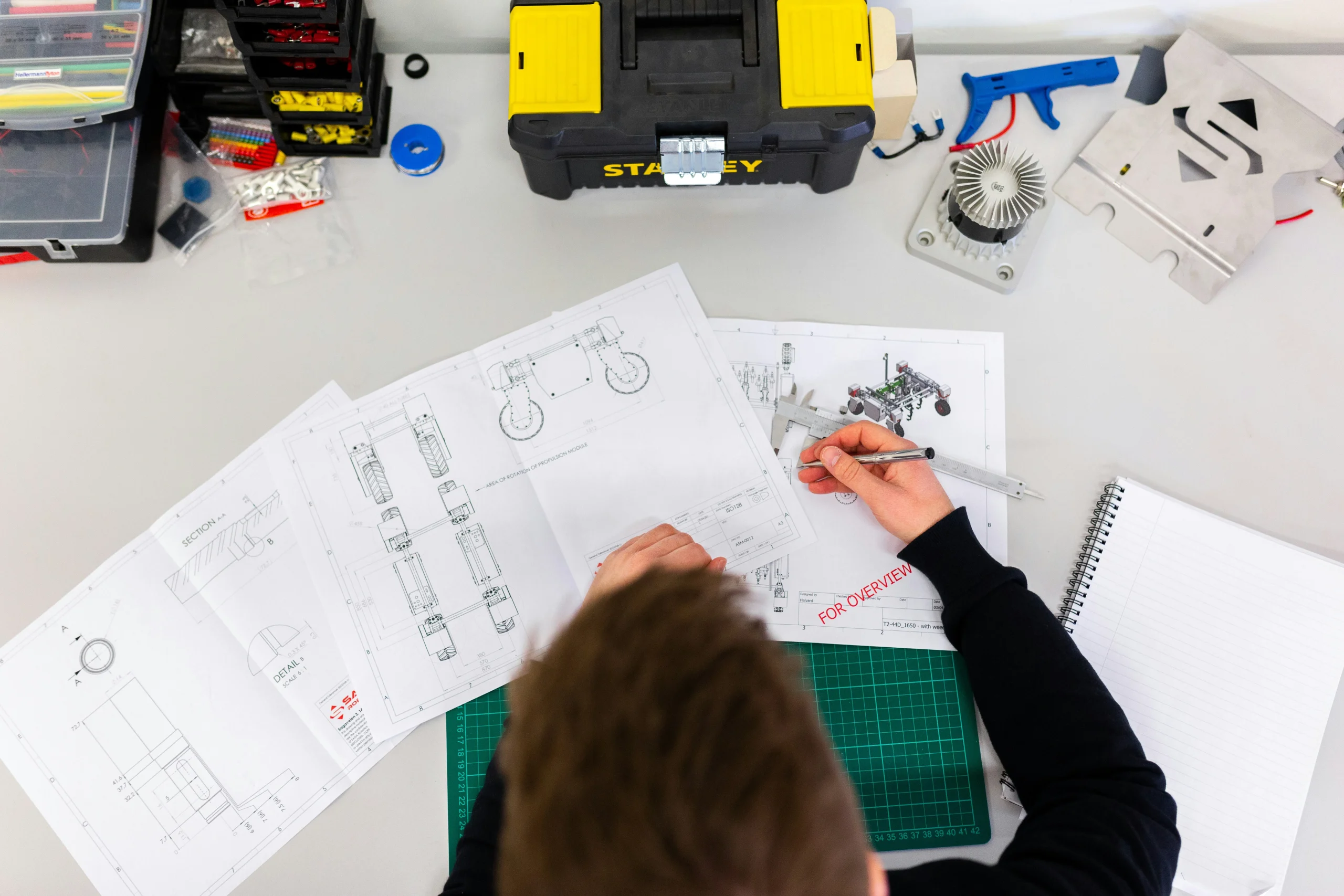

2. On-Site Installation Overview

The entire production line is arranged compactly to fit the customer’s existing factory space, while maintaining smooth material flow. The on-site layout includes:

(1) Primary Shredding Section

- A heavy-duty shredder breaks down whole PCB boards into smaller fragments.

- Handles computer motherboards, TV boards, CCL sheets, and mixed electronic scraps

- Slow-speed, high-torque design reduces dust and avoids metal loss

(2) Fine Crusher & Pulverizing System

- Multiple-stage crushers reduce material to a controlled particle size , preparing it for separation.

- Low-noise chamber

- Wear-resistant knives

- Intelligent load balancing to prevent clogging

(3) Airflow + Electrostatic Separation System

- This is the core process of the line.

- Airflow separator removes lighter resin powder and fiber

- Electrostatic separator achieves high purity metal separation

- Final metal purity reaches ≥ 98%, ensuring maximum economic return

(4) Pulse Dust Collection & Negative Pressure System

- Vietnam’s environmental regulations require clean emissions.

- Complete dust capture from shredding to separation

- Pulse jet filters ensure the workshop remains dust-free

- Negative pressure prevents fugitive emissions

(5) Central Control Panel

A PLC-based intelligent control system manages all motors, feeders, separators, and dust collectors.

Operators can monitor the system status and alarms in real time, ensuring safe and reliable performance.

3.Customer Benefits

(1) Economic Benefits

- Significantly increased recovery of copper, aluminum and precious metals

- Lower operational costs due to automation

- Fast ROI thanks to high metal resale value

(2) Environmental Benefits

- Meets Vietnam’s industrial air-quality standards

- Zero wastewater discharge process

- Safe handling of e-waste, reducing environmental impact

(3) Operational Advantages

- Reduced labor from 10 people to 3 people per shift

- Modular design allows future expansion to 1,000 kg/h

- Comprehensive training provided by our engineering team