What is a gold stripping machine?

In a world where electronic waste is rising at record-breaking speed, recovering high-value precious metals has become not just a business opportunity—but a necessity. Gold recovery from e-waste is projected to grow by 7–9% annually, driven by smartphones, computers, and consumer electronics.

But here’s the biggest challenge recyclers face: How do you separate gold safely, efficiently, and profitably?

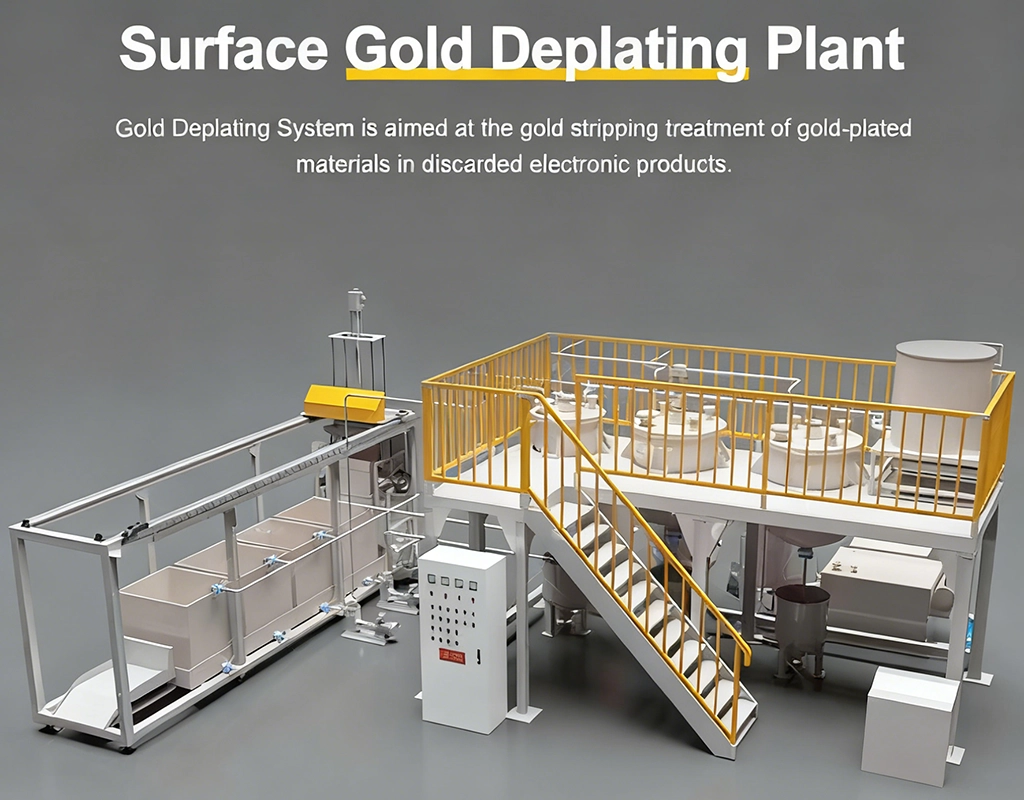

This is where a gold stripping machine (also called a gold deplating system) steps in. Designed to strip, separate, and recover gold from circuit boards, CPUs, connectors, and electronic components, this machine is transforming how small recycling workshops and large refining plants handle gold recovery.

What Is a Gold Stripping Machine?

A gold stripping machine is a specialized equipment used to remove (“strip”) gold plating from electronic waste such as waste circuit boards, computer CPUs, motherboards, connectors, and leftover materials from electroplating factories.

Unlike traditional acid-based gold recovery—which is dangerous, messy, and inefficient—modern gold stripping machines use controlled chemical solutions, closed-loop filtration, and high-efficiency reaction systems to safely separate gold from substrates like copper, nickel, and alloys. It removes gold from scrap materials cleanly, quickly, and with high recovery rates—perfect for precious metal refining plants and e-waste recycling facilities.

How Does a Gold Stripping Machine Work?

- Material Loading – Electronic scraps (like CPUs, gold fingers, boards) are placed into the reaction tank.

- Chemical Circulation Starts – A specially formulated stripping solution flows through the tank.

- Gold Dissolution – The solution removes only the gold layer, leaving base metals intact.

- Solution Filtering – Dissolved gold enters filtration or precipitation systems.

- Gold Collection – Gold is recovered as flakes or powder with high purity.

- Closed-Loop Solution Recycling – Many machines reuse chemicals, reducing cost and pollution.

This process is fast, clean, and remarkably efficient, with recovery rates reaching 98% or more in well-calibrated systems.

If your business deals with electronics, PCB manufacturing, or metal refining, a gold stripping machine is absolutely worth investing in.

It boosts recovery rates, increases profit margins, protects workers, and reduces environmental impact.

As gold prices continue climbing and e-waste grows, the demand for safe, efficient stripping equipment will surge.